RESEARCH PAPER

Adsorption dryer for use in railways

1

Sieć Badawcza Łukasiewicz - Poznański Instytut Technologiczny, Polska

Submission date: 2022-04-28

Final revision date: 2022-07-27

Acceptance date: 2022-07-28

Online publication date: 2022-07-31

Publication date: 2022-08-29

Corresponding author

Kacper Matusiak

Sieć Badawcza Łukasiewicz - Poznański Instytut Technologiczny, Sieć Badawcza Łukasiewicz - Poznański Instytut Technologiczny, Estkowskiego 9, 61-755, Poznań, Polska

Sieć Badawcza Łukasiewicz - Poznański Instytut Technologiczny, Sieć Badawcza Łukasiewicz - Poznański Instytut Technologiczny, Estkowskiego 9, 61-755, Poznań, Polska

Rail Vehicles/Pojazdy Szynowe 2022,1-2,77-85

KEYWORDS

TOPICS

ABSTRACT

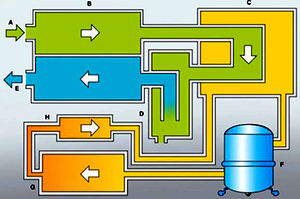

Pneumatic brake, which use compressed air as a working medium, is the main brake of rail vehicles. The equipment used in the braking system requires sufficiently clean, without water vapour medium to work properly. Removing water vapour from the air prevents condensation and ice formation during winter, which guarantees correct brake operation. For this purpose, adsorption dryers are used in the railways to ensure the required pressure dew point value.

This article includes an overview of available compressed air drying methods, the results of calculations and bench test of the dryer prototype developed at the Institute. Assumptions and requirements for the device intended for use in railways are based on European standards and UIC cards.

REFERENCES (23)

2.

Atuonwu C., van Straten G., van Deventer H.C. et al. Improving adsorption dryer energy efficiency by simultaneous optimization and heat integration. Drying Technology. 2011, 29, 1459-1471. https://doi.org/10.1080/073739....

3.

Atuonwu C., van Straten G., van Deventer H.C. et al. Model-based energy efficiency optimization of a low-temperature adsorption dryer. Chemical Engineering Technology. 2011, 34(10), 1723-1732. https://doi.org/10.1002/ceat.2....

4.

Xu B., Zhang X., Zhang S. et al. Research on double tower dryer based on air brake system of rail vehicle. Journal of Physics: Conference Series. 2021, 1948, 012126. https://doi.org/10.1088/1742-6....

5.

Dajeni M., Bartels P.V., Sanders J.P.M. et al. Computational fluid dynamics for multistage adsorption dryer design. Drying Technology. 2008, 26(4), 487-502. https://doi.org/10.1080/073739....

6.

Goliwąs D. Uzdatnianie sprężonego powietrza w pojazdach trakcyjnych. Pojazdy Szynowe. 2007, 4, 31-43. https://doi.org/10.53502/RAIL-....

7.

Kang S.-W., Chang S.-H., Kim H.-J. et al. A study on operating method to save energy from the adsorption dryer in the process of purifying compressed air. Journal of Society of Korea Industrial and Systems Engineering. 2016, 39(3), 180-191. https://doi.org/10.11627/jkise....

8.

Code UIC 612-2. Specific sub-system requirements (traction, braking, etc.) for EMU/DMU, locomotives and driving coaches (Rolling stock sub-system requirements, requirements for economic purposes, requirements for railway standardisation), 2009.

9.

Kozlov V., Piskun E., Ilicheva O. Investigation of the processes of adsorbent regeneration by compression heat in an adsorption dryer of compressed air. Matec Web of Conferences. 2020, 324, 02009. https://doi.org/10.1051/matecc....

10.

Litchfield R.J., Liapis A.I. An adsorption-sublimation model for a freeze dryer. Chemical Engineering Science. 1979, 34(9), 1085-1090. https://doi.org/10.1016/0009-2....

12.

Polski Komitet Normalizacyjny PN-EN 50125-1 Kolejnictwo – Warunki środowiskowe stawiane urządzeniom – Część 1: Tabor i wyposażenie pokładowe. 2014.

13.

Polski Komitet Normalizacyjny PN-EN 60721-3-5 Klasyfikacja warunków środowiskowych Część 3-2: Klasyfikacja grup czynników środowiskowych i ich ostrości. Transport i przeładunek. 2018.

14.

Polski Komitet Normalizacyjny PN-EN 61373 Zastosowania kolejowe. Wyposażenie taboru kolejowego. Badania odporności na udary mechaniczne i wibracje. 2011.

15.

Ripol-Saragosi L. Compressed air mechanical drying for railway branch of Europe. Transport Problems. 2010, 5(4), .

16.

Ripol-Saragosi T., Ripol-Saragosi L. Compressed air drying process energy consumption decrease by intellectual management systems implement. International Multi-Conference on Industrial Engineering and Modern Technologies. 2019, 1-6. https://doi.org/10.20858/tp.20....

17.

Rusinski E., Czmochowski J., Smolnicki T. Zaawansowana metoda elementów skończonych w konstrukcjach nośnych. Oficyna Wydawnicza Politechniki Wrocławskiej. Wrocław 2000.

18.

Schaumann S.P. Air compressor systems for passenger rail applications. International Compressor Engineering Conference. 2008, 1918, 1-9. https://docs.lib.purdue.edu/ic....

19.

Sureshkannan V., Vijayan S., Lenin V.R. Design and performance analysis of compressed air adsorption dryer with heatless regeneration mode. Heat and Mass Transfer. 2022, 58, 631-641. https://doi.org/10.1007/s00231....

20.

Techniczna specyfikacja interoperacyjności odnosząca się do podsystemu „Tabor — lokomotywy i tabor pasażerski” systemu kolei w Unii Europejskiej nr 1302/2014. 2014.

21.

Tuch T.M., Haudek A., Muller T. et al. Design and performance of an automatic regenerating adsorption aerosol dryer for continuous operation at monitoring sites. Atmospheric Measurement Techniques, 2009, 2, 417-422. https://doi.org/10.5194/amt-2-....

23.

Zhang Y., Zhang Q.M., Wang R. et al. Safety analysis and fault automatic recognition technology of regenerative adsorption dryer. IOP Conference Series: Earth and Environmental Science. 2019, 237(3), 032058. https://doi.org/10.1088/1755-1....

We process personal data collected when visiting the website. The function of obtaining information about users and their behavior is carried out by voluntarily entered information in forms and saving cookies in end devices. Data, including cookies, are used to provide services, improve the user experience and to analyze the traffic in accordance with the Privacy policy. Data are also collected and processed by Google Analytics tool (more).

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.